Test Electronics

BON - Bed of Nails Testers

All Products

Modular Design Extra Easy Upgradeability

New HDPE plastic plates for extra easy machine ability and upgradeability. Designed for Research & Development and Pre-Production where product engineering changes are a weekly issue. The primary design focus is easy upgradeability. In R&D and Preproduction, design changes can happen every week. This fixture unlike normal test fixtures was designed to be easily taken apart and updated. Disassembling a normal bed of nails test fixture over and over again can be a major disaster with wire breakage and test pin bending issues. The modular design of the Rand fixture allows for easy disassembly without flexing the wires or risk of bending test pins. The Rand fixture provides complete easy access for machining, drilling and wiring updates.

Modular Design Easy Upgrade ability

Designed for Research & Development and Pre-Production environments to support often reoccurring product design changes. The primary design focus for this fixture is ease in applying engineering changes and resilience to the abuse of applying multiple engineering changes without damage. In R&D and Preproduction, design changes and updates can occur every week. This Rand fixture, unlike normal test fixtures was designed to be easily taken apart and updated. Constantly disassembling modifying and reassembling a normal bed of nails test fixture over and over again can be a major disaster with wire breakage and test pin bending issues. The modular design of the Rand fixture allows for easy disassembly without flexing the wires or risk of bending test pins. The Rand fixture provides complete easy access for multiple updates requiring machining, drilling and wiring changes.

Insert Based Design High Durability

Production volume test fixture with swappable test plates, front and rear panel inlays, and multi-testing compatibility with process carrier pallets. Swappable test plates provide the ability for one fixture base to support a variety of units under test. Interchangeable front and rear panel inserts provide further customization. Interoperability with process carrier pallets provide multiple board testing capabilities, panelized testing, and flex circuit testing. A selection of interfaces to general testing equipment provide for a wide selection of customized testing features.

Test 6 sides Ergonomically Designed

6 sided Bed of Nails circuit board test fixture. Probes top bottom and all 4 sides. Central camming mechanism pull plates inward. Mechanically or electrically actuated options. Designed primarily for testing products in plastics. Side access electrically probes outside panel connectors. The unit will also optically read LEDs and key segments off LCD displays. Solenoids will press buttons and servos will turn selector switches. DC motors are used to adjust multiple turn potentiometers. Microphone will detect audio output tones. Top and bottom of circuit boards can also be probed if removable access panels are available. This unit will also probe all 6 sides of a circuit board. This is typically utilized in applications where connector testing is required.

Fully Adjustable 2 Hour Fixture

Designed for quick test development. This fixture can be configured to probe almost any circuit board in just a few hours. Once the perfect test is developed, move this light weight fixture out to the production floor to evaluate your production line test strategy prior to buying permanently drilled test fixtures, or while waiting for your drilled fixtures to be delivered. The AdjustaBON competes with the Flying Prober. There are many advantages over the flying prober. Setup is simple and intuitive and can be much quicker than programming a flying prober. Small size provides versatile bench top operation right where you need it. Maintenance costs are insignificant in comparison. The total cost of this fixture is in many cases less than the yearly maintenance cost of a flying prober. It would be possible to buy one of these fixtures every year for the price paid just to maintain one flying prober and it is about 1/20th the purchase price

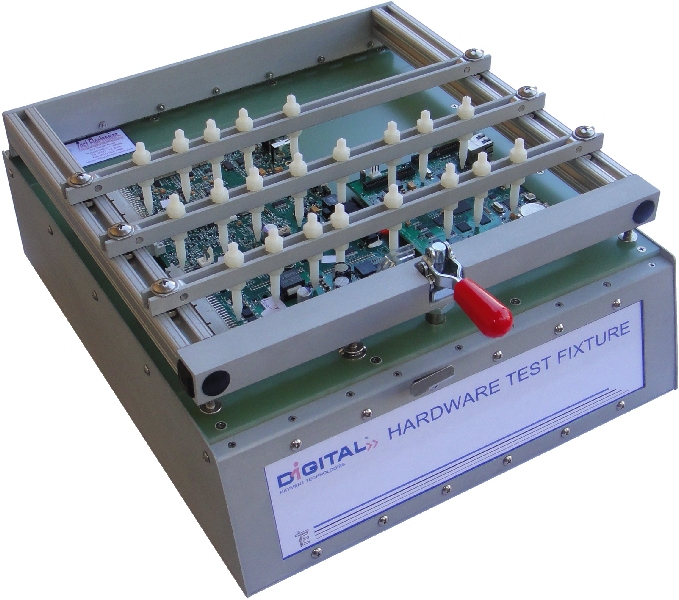

Heavy Board Protected Test Pins

Designed for testing heavy massive boards. Boards with heavy components like large transformers and inductors can destroy normal test fixtures. This design utilizes a 3 plate system where an internal lever actuated sub plate containing the test pins raises to probe the circuit board when the handle is pulled. Heavy boards can bend and break exposed test pins. Similarly large boards which need to be probed by very small delicate test pins can also benefit from this protected test fixture design. This fixture is recommended in situations where there is a high board mass to pin size ratio and pin protection is required. Front and rear panel modular inserts allow for easy updates and customizations to the user hardware interface.